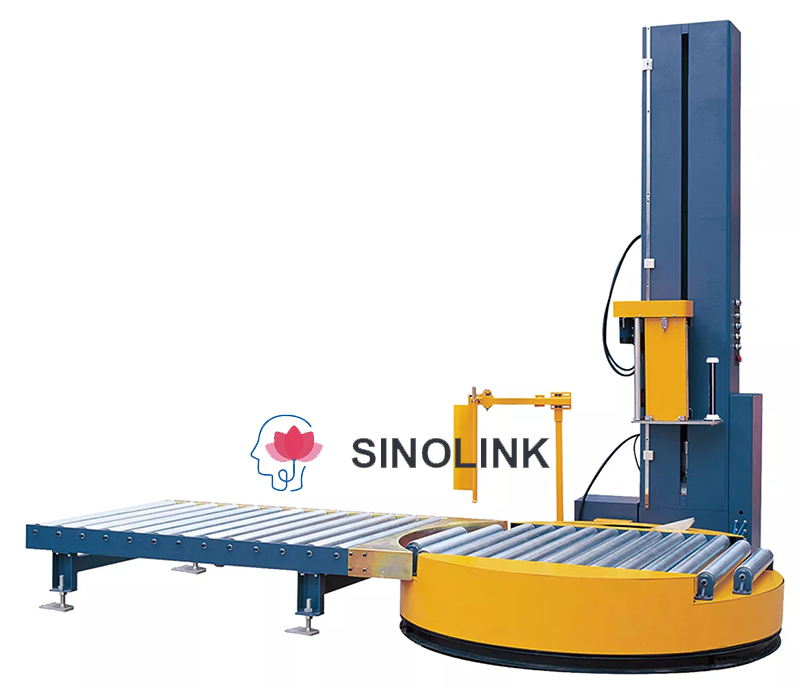

Full Automatic Turntable Wrapping Machine

Main Technical Data Of Hot Sales For Full Automatic Turntable Wrapping Machine

1. Pallet SpecificationSize: L x W x H : 1300 x 1300 x 2000 (mm)Pallet Weight: 1000kgs;

2. Conveying machine size:height 550mm*width 1500mm(customer oriented);

3. Packing capacity:40 load/h;

4. Requirement for packing:from one third of 15cm pallet to the overtop of the load but not exceed 15cm;

5. Site :indoor and proper temperature zoon.

OPERATION OF Hot Saels For Full Automatic Turntable Wrapping Machine

The conveying roller will transport the pallet of drink products to the location of rotary wrapping machine, automatically start wrapping till to finish packing .and then film is cut automatically ,after it ,the pallets will be transported by conveying rollers.The procedure of next will be alike.

Main electrical parts and spare parts of Full Automatic Turntable Wrapping Machine

Component name | Brand |

PLC | OMRON(Standard configuration) |

Touch screen | OMRON(Standard configuration) |

inverter | MCGS |

Photoelectric switch | OMRON |

Proximity switch | OMRON |

Circuit breaker | Schneider |

Mini circuit breaker | Schneider |

Contactor | Schneider |

Solenoid valve | Standard configuration: YADEKE |

Cylinder | Standard configuration: YADEKE |

Limit switch | Schmeisai |

Master device | Schneider |

Bolts and other fasteners | Grade 8.8 |

DC24V-3A power supply shall be provided separately, and Mingwei shall be selected as the DC power supply; | |

Packing material of Full Automatic Turntable Wrapping Machine:

Stretch film:3 inched diameter of core,500mm in width,the diameter of film is 260mm,film thickness:20-35μm

Site preparation:

Compressed air source:

1. pressure: 0.5-0.7 MPa

2. Air consumption: no oil and water power supply

3. Main power: 380v(+/- 10%)/3 phase/50Hz(+/- 1Hz)

4. Power capacity: ≈3kw

Supply range:

Automatic online turntable film wrapping machine(1 set)

Turntable arm driving system(1set )

1. Motor & inverter ,speed adjusted and brake 。

2. Turntable speed motor:SEW

3. Power :P=1.1KW

4. Turntable speed:n=10-15rpm(speed adjusted and brake)

Film carriage parts(1set)

1. Film carriage adopts chain drive for lifting, which is stable and reliable;

2. Film carriage lifting driving reducer motor:turbine worm reducer;

3. Motor power: 0.37kw;

4. Film carriage stretching ratio :1 : 2.5

5. Lifting reducer motor brand:SEW

Safety guard fixture(1set)

1. The feeding and cutting film mechanism are equipped with safety protection devices and protective nets, and the door locks of the protective nets are interlocked with the equipment. When the safety doors are opened, the equipment stops running;

2. Size of protective nets( Subject to drawings)

3. After the equipment runs, the stop position is at the left bottom end, and the protective net door is at the right bottom end;

4. The door protector uses a plug type switch.

Film carriage (1 set)

1. Photoelectric switch is installed on film carriage to automatically detect the height of goods;

2. AC motor power capacity:0.37KW;

3. Stretch ratio:1:2.5,film feeding speed adjusted;

4. Approaching switch will work for motor driving if there is no film break;

5. Membrane rack follow-up mechanism;

6. The film carriage’s film feeding arm rotates, and the proximity switch controls the start and stop of the film feeding motor to achieve the follow-up of film feeding.

Auto film attached and cut(1 set)

Pneumatic system:FESTO

Conveying roller (1 set)

1. Bearing capacity: 2000Kg

2. Conveying speed: 140mm/s

3. Width of conveyor line: 1500mm

5. Height of conveyor line: 550mm

6. Reduction motor: 0.75KW

7. Material of roller conveying frame: galvanized and passivated carbon steel

8. The conveyor can be operated in reverse manually.

Pneumatic system

Air supply : user provide

Parts: festo

Electrical system of Full Automatic Turntable Wrapping Machine

1. PLC programmable control;

2. Touch screen operation, winding layers and times can be set;

3. Photoelectric switch can automatically sense the height of goods;

4. Slewing ring drive, accurate positioning;

5. Digital parameter setting: cantilever rotation speed, membrane rack lifting speed, membrane rack out speed;

6. The machine is equipped with automatic, manual and side switch functions to better ensure the operation of the packaging system;

7. Warning light is set for machine operation.

Technical service of Full Automatic Turntable Wrapping Machine

Installation(in China):

We will send our field engineers to your factory for installation and test running, you should make good site preparation

Training(in China)

We will train your guy to operate and repair machine and can reach to a high lever, usually solve the problems in an hour

Guarantee(in China)

1 year guarantee

Machine picture (for reference only):

More information, please contact with us at any time. We will help to save cost and recommend the best wrapping machine for you. Looking forward to your inquiry at any time.

Ady

WhatsApp:+86 15634865861